Originally Posted by

MICHAEL

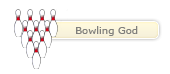

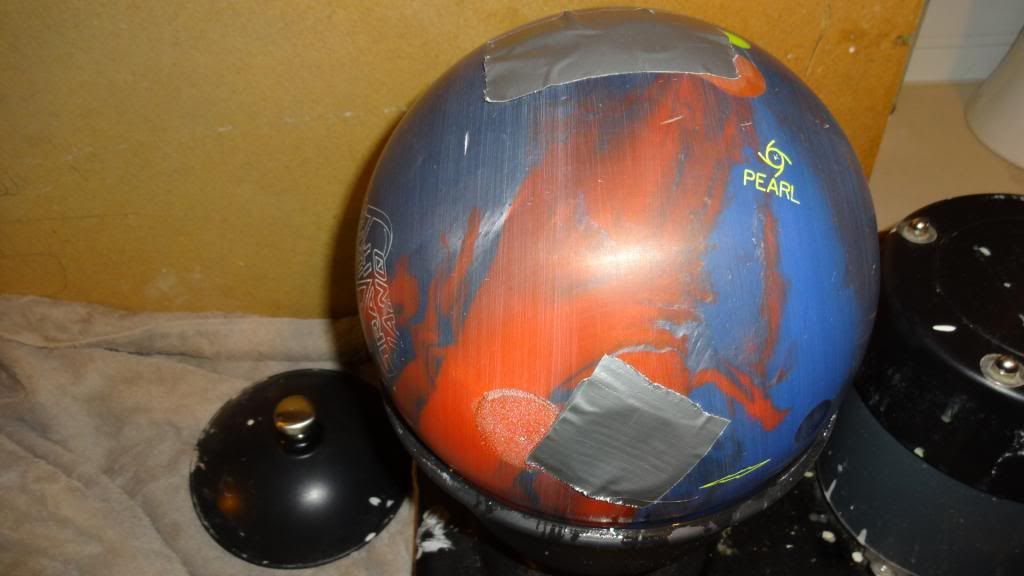

hummm now you throw this at me!!?? If you look at the pictures I posted, that was a 1000 abrasion pad, only thing I did wrong was method of sanding position of ball. So you are saying If I do your method to get the 1500 surface,

1. use a a 1000 or 2000,,, I don't have a 1500, and the correct postion of ball for the 4 side surfacing

2. use the Reacta Shire,,,, (which is as I remember a 1500 polish combination)

Remember now the picture I posted was after using a 500 with pressure, then 30 seconds,,, then a 1000 light pressure for 15 seconds, then Reacta Shine.

And you can see the groves in the ball.....

To the naked eye, it did not show, but I noticed the camera really showed the groves..

Ok the above is what you do for a out of box 1500,,,, with only two steps..

in your tread before that you said go through many more steps??? which is right??? LOL

Bookmarks